Operational issues are the number-one cause of supply chain disruptions in domestic manufacturing. Robotic Process Automation has proven to be an effective way to fight operational inefficiencies that cause these problems, but only a few companies have started using RPA technologies.

Robotic process automation (RPA) refers to the use of software bots or robots to perform tasks that typically require human intervention. The impact of operational problems on supply chains costs companies billions annually, according to a report by IBM.

Many factors contribute to these disruptions, but operational issues are the number-one cause. RPA has proven to be an effective way for manufacturers to fight these inefficiencies and improve their productivity, but only a few have adopted this technology. However, with the right guidance, more organizations can use RPA solutions to eliminate these operational problems before they negatively impact their business.

Manufacturers are eager to make sure they are using all available resources to ensure optimal performance during each step of the supply chain. RPA can help reduce operational problems by making companies more efficient and opening up time for them to focus on innovation, instead of mundane issues like invoice verification.

RPA can help reduce operational problems by making companies more efficient and opening up time for them to focus on innovation, instead of mundane issues like invoice verification.

In this article, we’ll look at how firms can use RPA to establish a more domestically focused supply chain strategy and minimize Covid-19 pandemic losses.

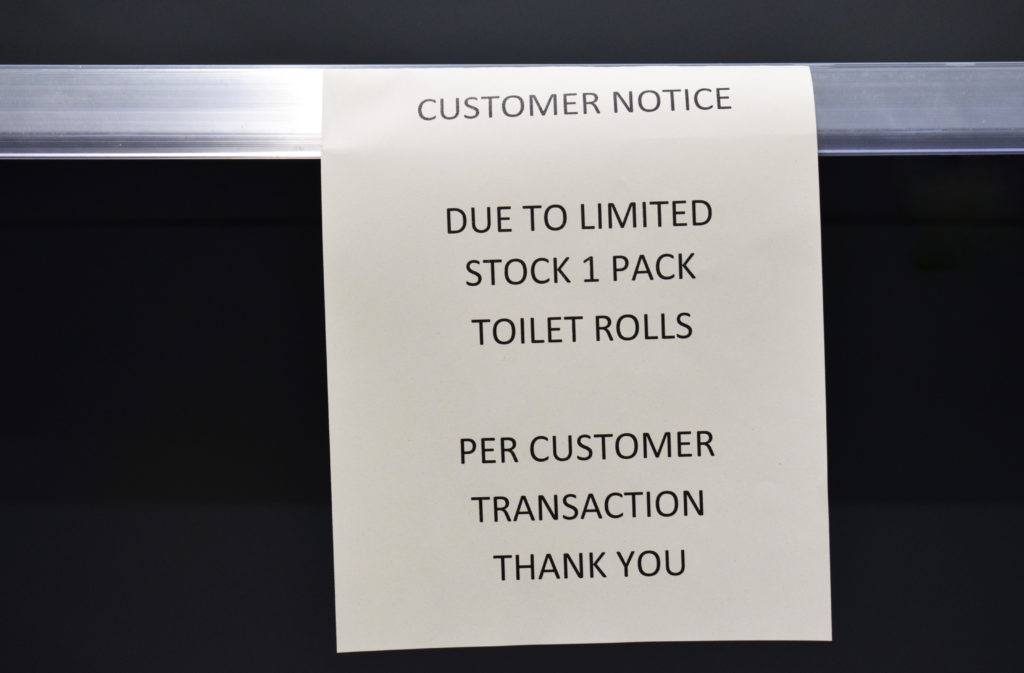

Covid-Related Supply Chain Problems

Supply chains all around the world have been struggling with the Covid-19 pandemic. In fact, a lack of supply chain visibility is what is most crippling to supply chains in America and Europe. The unfortunate truth is that right now, most companies still rely on spreadsheets, shared drives, and fax machines to stay connected throughout their supply chain networks.

The unfortunate truth is that right now, most companies still rely on spreadsheets, shared drives, and fax machines to stay connected throughout their supply chain networks.

With more than half the world’s production capacity located outside of North America and Europe, many American manufacturers are struggling with understanding where all of their materials actually come from. This lack of transparency makes it hard for organizations to make smart business decisions about where they should be sourcing raw materials from or how much inventory they need to keep on hand.

4 Steps to Curb Supply Chain Disruptions Caused by Covid-19

Here are four steps that all manufacturers can take to increase their visibility and strengthen their supply chains:

- Leverage RPA Solutions to Reduce Human Error

Using RPA technology, companies can automate repetitive, time-consuming processes like data entry, contract management, invoice processing, and more.

One of the best ways for manufacturers with limited resources to quickly gain a competitive advantage is by using RPA solutions to simplify everyday business operations. By reducing the number of manual actions needed for each step in the process, companies become much more efficient, allowing more time to focus on long-term strategies.

- Create a More Domestic Strategy with Supplier Relationship Management

Manufacturers who are hedging their bets on international suppliers are not only risking the loss of valuable data, they’re also risking damage to their relationships with these partners. The current state of affairs is leading many organizations down an expensive path that isn’t sustainable in the future—one that requires them to hire more people and expend valuable resources trying to keep track of external information.

To reduce a company’s risk of Covid-19 pandemic-related supply chain disruptions, manufacturers should consider creating supplier relationship management (SRM) programs using RPA solutions instead. Using this technology, companies can automate the process of collecting, organizing, and reporting external data to help reduce operational expenses while also increasing visibility into the sourcing process.

- Implement Digital Transformation Initiatives with RPA Solutions

As automation solutions for supply chain management become more popular, manufacturers are looking for ways to get ahead of competitors by implementing digital transformation initiatives in their organizations. By incorporating systems like ERP and WMS within their supply chains, companies can streamline inventory management duties across the entire organization.

Using RPA in this way is becoming increasingly popular due to how quickly it can be implemented without requiring extensive resources or major technological overhauls. Many manufacturers are already leveraging robotic process automation to increase productivity throughout the planning of their supply chains, allowing them to reduce costs and better manage inventory across their networks.

- Use RPA Solutions to Track the Entire End-to-End Process

In order to ensure that your supply chain is as efficient as possible, organizations need a way to understand the entire end-to-end process from materials sourcing all the way through production, delivery, and beyond.

Integrating systems like ERP with other technologies allow companies to track every step of this process so they can quickly address any challenges or problems they might face along the way.

One of the best ways manufacturers can stay informed about their products’ origins is by using Robotic Process Automation solutions for tracking purposes.

By developing RPA that uses bots to extract data from disparate systems, organizations can heighten their visibility into the manufacturing process without requiring extensive resources.

Advantages of a Strong RPA Implementation

Data is becoming an increasingly important aspect of doing business. With that said, larger companies are finding that they need more ways to manage the vast quantities of data their businesses are generating on a daily basis.

Many organizations are turning to Robotic Process Automation solutions for tracking purposes because these systems enable them to gather and organize external data from various sources without disrupting or slowing down day-to-day operations.

By using this technology, manufacturers can make sure all aspects of their supply chains remain completely transparent at all times so they can quickly identify any potential problems before they become major issues.

Improve Efficiency

RPA solutions can help manufacturers stay more productive and efficient by automating routine, manual tasks that do not require human intervention.

For example, if a company is using a third-party logistics firm to handle its invoices, the RPA software bot would automatically verify invoice information with no human interaction needed. This saves time for employees who are better suited to handle other business processes.

Additionally, as these bots become more advanced as they learn from each new task they complete, they will continue to increase productivity over time without needing additional training or downtime for upgrades.

In addition to increasing efficiency across all departments, RPA solutions also automate specific supply chain functions that contribute directly to operational problems. The most common of these include:

- Processing inbound shipments

- Performing in-house verification of the invoice detail, line items, and amounts

- Creating inhouse exceptions when discrepancies are found between the shipped product and the invoice associated with it

- Printing out shipping labels or preparing them for printing to ensure efficient processing of orders at distribution centers around the nation. This also increases operational efficiency by reducing delays caused by poorly labeled products. RPA can be used to improve label creation by detecting patterns based on previous label formatting for more efficient distribution center workflows.

- Assisting with inventory management processes, including receiving inventory into an electronic system, verifying quantities received against purchase orders, and reporting suppression of material discrepancies.

- Transferring inventory between warehouses, both internal and external to the organization, based on business requirements. This function assists supply chain professionals with optimal order fulfillment strategies.

Enhance Collaboration

RPA is also an effective way for manufacturers to improve collaboration across all departments that contribute to the successful operation of their supply chains. As automated systems take over routine tasks like verification and exception handling, these employees are freed up to focus on more critical work where their unique abilities can make a difference in creating new solutions to problems they didn’t even realize existed before automation.

RPA solutions allow workers who may be struggling with particular aspects of their job or may simply not enjoy it as much as other tasks to make the most of their abilities.

RPA can also be used to enhance collaboration across third-party logistics firms and customers by fully automating the process of product returns while maintaining high-quality service for requests that require human interaction.

The bot automatically receives a request for return from the customer, verifies that it is within the time frame allowed by the company’s return policy, then assigns an order number to track where it goes through each stage in the process. Once processed, the bot sends out notification emails to both parties letting them know what action was taken during each step in the process.

Continue Innovation

When a company implements RPA, they are forging a path into the future of automation that minimizes human involvement in their supply chains. As companies continue to improve their RPA solutions by adding new features and making them more efficient at completing tasks, these bots will continue to increase the productivity of their employees as well as foster creativity and problem-solving skills across all departments.

For this innovation to take hold in manufacturing, professionals from third-party logistics firms need to offer advice on how to implement RPA solutions that benefit manufacturers’ supply chains. Likewise, manufacturers should seek out logistics partners who have experience implementing innovative supply chain technology like RPA into client operations.

Final Thoughts

In using RPA technology, companies can automate repetitive, time-consuming processes like data entry, contract management, invoice processing, and more. One of the best ways for manufacturers with limited resources to quickly gain a competitive advantage is by using RPA solutions to simplify everyday business operations.

By reducing the number of manual actions needed for each step in the process, companies become much more efficient. Additionally, RPA software bots can provide visibility into the supply chain process that many organizations would not be able to achieve otherwise.